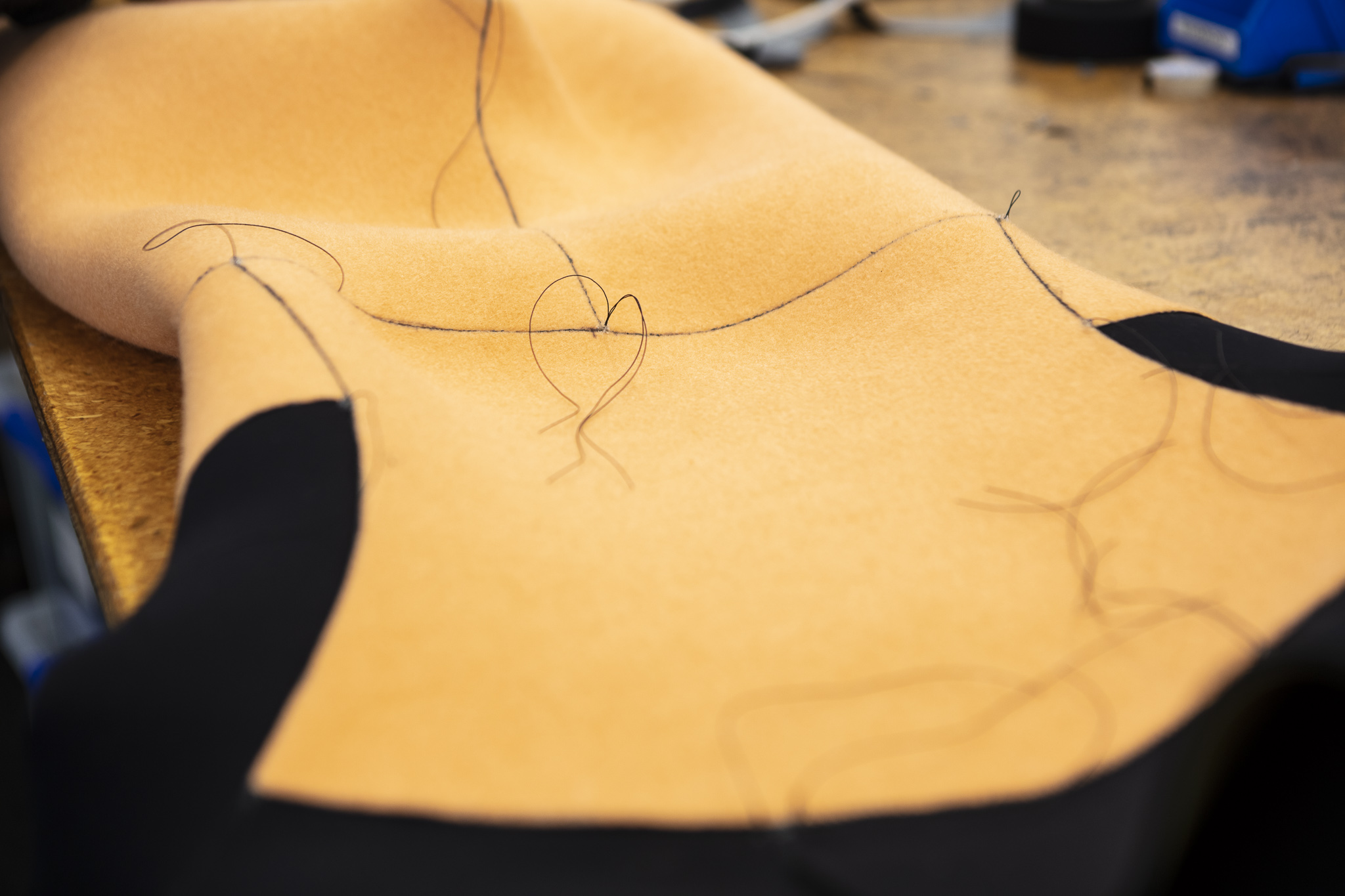

Lying on a table in Seventhwave’s Ferrymead factory in Christchurch is a fluffy orange wetsuit that doesn’t look anything like the wetsuit manufacturer’s flagship Yamamoto suits. Sarah smiles, she lifts the wetsuit up and explains the prototype to me.

“I haven’t surfed in this one yet,” she admits with a cheeky laugh. “But I’m about to – hopefully this afternoon. It is made of Yulex neoprene and it’s only a 3/2, normally I wear a Yamamoto 3/2, which is fine, but I’m not so sure with this one.”

The water temperature at Sumner Beach, Christchurch, today hovers around 10°C. I’d be reaching for my 4/3, but Sarah Armstrong-Park, the owner of Seventhwave Wetsuits for the past four years, has some testing to do.

“We’re sampling the Yulex plant-based neoprene,” she explains. “Just to see how it performs and how it lasts. We’re not having too much success with it at the moment, but we’ll keep giving it a bit of a try. We don’t want to use petroleum-based neoprene because it doesn’t last, it’s bad for the environment and it’s cold. We’re looking at different neoprene materials that are better for the environment.

Sarah said the main challenge with Yulex was its resistance to heat … or lack of resistance.

“Some of the Yulex neoprene melts under heat,” she offers. “So when we need to put tape on a wetsuit you need to heat it on and it melts, which isn’t ideal. Then, if you want to repair that you need to put an insert in and you need to heat it also – so you wouldn’t actually be able to repair it. For us, that’s a real issue. We just have to figure that challenge out – maybe we can mix Yamamoto with Yulex instead.”

When she tells me how far off this material is from hitting the shelves in a production wetsuit, I feel like I’ve had a glimpse into the future. She agrees.

“Producing a wetsuit with Yulex is a long way down the track,” she smiles. “We have to sample it first – put it on our highest users and get them to thrash it and make sure it’s going to last.”

“That’s the whole point when you buy a New Zealand-made wetsuit, it is more expensive, but we stand behind it for durability and longevity. So we need to know that it’s going to perform and last, like the Yamamoto does. So realistically, this is probably a couple of years off I’d say.”

“That’s the whole point when you buy a New Zealand-made wetsuit, it is more expensive, but we stand behind it for durability and longevity. So we need to know that it’s going to perform and last, like the Yamamoto does.”

Seventhwave Wetsuits was born in Christchurch in 1987 – built from scratch by Geoff White and the late Paul Zarifeh. The pair instantly stumbled across Yamamoto – a premium limestone-impregnated neoprene that was sustainably superior than other neoprene. It also happened to be warmer, which suited their ambition to provide South Island surfers and water users with the best experience possible year round.

For the past 33 years, Seventhwave wetsuits have forged a place in watersport with Yamamoto neoprene at its core. Only in recent years have international manufacturers started to experiment with the more expensive neoprene.

“I just love how quick they dry,” offers Sarah. “I couldn’t imagine putting a wet wetsuit on again. I just couldn’t even bring myself to do it and they stay light, which is important – especially in winter when you’ve got lots of neoprene on. You don’t want it to be weighted down with the water. I find that when I first get my suits, they do feel a bit tighter. They need to be in the water for a few sessions before they feel like they’ve just softened up a bit.”

Staying at the cutting edge of wetsuit technology is top of Sarah and partner Leif’s agenda. They bought Seventhwave from Paul in 2015 and have been bedding in their ideas for the future. But it hasn’t been an easy transition.

“It has been a bit of an experience – good and bad,” offers Sarah with a large sigh. “My eyes have been opened to New Zealand manufacturing and just how difficult it is. It has changed my perspective and my buying decisions, that’s for sure. Being in the bottom of the world – we’re just so small. Minimum quantities are a big deal. Also, there’s not really any other people to talk with about our processes. Like when you’re trying to explore new things and find better ways to do something, there’s not really someone to go, hey, how did you guys do this? Or, what are you using? Or, what machinery did you get? You’re left to explore everything on your own and just figure it out.”

Wetsuit manufacturing in New Zealand is very small. Apart from Seventhwave there is just one other manufacturer, Seaquel, based in Auckland, that makes dive suits.

“But they’re just same as us really,” admits Sarah. “The cost of the neoprene and the cost of shipping is just huge.”

Apart from the additional cost and transport of raw materials with these premium suits, Sarah said their manufacturing costs were much higher when compared with the factories of Asia, which had a very low cost base.

Nearly all the major international surf brands’ wetsuits are made in the very same factory: Sheico in Taiwan, with some also made in Thailand and in China.

“It absolutely makes a difference – we’ve got New Zealand staff that we need to pay New Zealand wages to,” she shares. “Obviously we considered the option of, could we send some of our products offshore, but then that really changes our entire brand and what we do, what we believe in. And custom-making wetsuits for our customers is a big thing for us as well – that has to be done in-house.”

From a revenue perspective Sarah admitted it had been a struggle.

“It’s been difficult – especially with our neoprene cost going up 20 percent,” she shares. “Any time you start making some improvement you feel like you’ve just been slapped with something else.”

After the first two years with Sarah and Leif at the helm, they made the decision to relocate from the Dyers Road store last summer – moving back into the Ferrymead building that had housed the original Seventhwave business from 1996-2010.

“The main reason we moved back was for the location,” Sarah explains. “We’re a premium brand and we wanted to reflect that in our environment. It’s really nice here – it’s changed our environment. We’ve got plants, we’ve got windows and dogs and, yeah, it’s a nice place to come to work.”

“We moved in October 2018 – so we haven’t really had a year to really tell if there’s been any significant difference,” Sarah adds. “We’re in the middle of rebuilding a new website right now so I’m hoping that will help our online sales, but it is definitely a challenge.”

Sarah and Leif employ a team of eight on a mixture of full and part-time, or six full-time equivalents. That doesn’t include the dogs, Ziggy and Baxter, who swirl happily around our feet.

“So that hasn’t changed really – that’s still the same as when Paul had the business. We just try to be more efficient. We’re always looking at ways that we can be more efficient and keep our staff costs down. The dogs don’t cost much to run here – just a few pats here and a few treats there,” she laughs.

When we interviewed Paul back in 2015 his biggest challenge was educating potential customers about the difference between a suit made out the back of his Christchurch factory and the cheaper options coming out of Taiwan. It seems that hasn’t changed.

“It’s the perceived value,” considers Sarah. “Our Enduro is $650 – for a winter suit that’s actually not that much more expensive than another brand’s suit. It’s a little bit stiffer, but that’s because the neoprene that we use in there is designed to last – that suit will last for a very, very long time. And when it starts getting holes in it, we design it so we can fix those holes. Keeping the suit out of the landfill for as long as possible is important to us.”

Seventhwave offers a wetsuit repair service and they see a lot of broken wetsuits from other brands. Sarah said that when a zip broke in a big brand wetsuit, which had happened frequently in the past few years, they discovered they were so glued in that you couldn’t actually get them out to replace them.

“It is that value of longevity – yes, you might pay a bit more to start with, but its longevity and service that make a difference,” she explains. “We’ll fix your suit and we’ll make sure we fix it quickly so you’re not without it for too long. It’s all about sustainability from start to finish. Once your suit is starting to get a bit old or you’re starting to feel it’s a bit cooler, we can plug it back up, put some new inserts in it and, you know, it’s still probably really good for another season, or it becomes your spare suit, or summer suit.”

The more I talk with Sarah the more I realise that she’s turned the sustainability dial right up in the business and she admits she intends to keep going in that direction. A quick survey of their operation and it is very clear that this isn’t just the waffle that some brands spout when probed by media about where the needle on their environmental compass points.

“We try and buy New Zealand made wherever we can,” Sarah begins. “So our YKK zippers are New Zealand made, our cords are Zealand made, our Velcro is New Zealand made, even down to our hand soaps – they’re all New Zealand made. So we try and support our own economy as well.”

“And then we try and use the best materials we can,” she continues with a smile. “All our Lycra is recycled – made from fishing nets. We make everything to be fixable or repairable. All our shipping and packaging – none of it uses plastics. We’ve tried to eliminate plastic out of our environment. Hopefully we’ll be able to plant some trees soon to offset our carbon. But at the moment it’s about growing the business to the point where it’s actually a sustainable business.”

“We try and use the best materials we can. All our Lycra is recycled – made from fishing nets. We make everything to be fixable or repairable. All our shipping and packaging – none of it uses plastics. We’ve tried to eliminate plastic out of our environment.”

As important as it is for businesses to chase the sustainable dream it has to be tempered with the fact that first that business must remain viable. Seventhwave seems to have that in hand and I think that’s encouraging. Nobody wins when a business with good environmental intentions can’t last the distance financially.

Thankfully, Seventhwave isn’t just relying on its flagship product with its premium wetsuits. They have been experimenting with new materials and in their pursuit to keep surfers as warm as possible have developed a line of super toasty base layers. It’s a bit like what Icebreaker did for outdoor clothing, but in the context of surfing. Sarah wanted to make the thinnest wetsuit she could and from that kernel of an idea the Seventhwave zirconium line of swimsuits and short johns evolved.

“The zirconium story is based around just trying to wear the thinnest suit that we can, but stay as warm as we can,” explains Sarah as she shows me a swimsuit, short john for men and socks with a gold lining. “So, that’s where the togs came from because you can layer that way – your arms are still free, so you’ve still got all your paddling ability. You’ve got all your movement, but you’ve got core warmth.”

“So we decided to make some zirconium togs and they’re amazing,” she smiles. “When you’re getting changed is actually one of the best things. You take your wetty off and you’re steaming, and you’re not standing in a cold southerly, rainy wind with just a bikini on – you’ve actually still got a warm layer. They’re awesome.”

Sarah’s daughter Janee, who works in the business with Sarah, Leif and the team, said the zirconium socks came out of the frustration of having a broken toe and not being able to wear split-toe booties, “so I got the girls to make some and they were amazing”.

The zirconium booties are more like socks than booties – designed for warmth rather than rock-hopping.

“So, you do get water in them, but it’s warm water,” explains Sarah. “You just never have numb toes ever again. Numb toes are gone. They’re so easy to get on and so easy to get off. They just roll out. Just leave them out to dry them. They’re just not so good on rocky beaches because of the softer fabric.”

Sarah said their next step was to make gloves out of the zirconium material.

“We just have to figure out how to make gloves out of it – right now our machinery doesn’t go around little things,” she explains. “And one of the issues of being at the bottom of the world is that it is very hard to find machinery without traveling around the world to try and locate it. So mittens was on my list of things to try instead, just to see if that works.”

It seems that magic of innovation that New Zealanders are renowned for comes easily to the surface at Seventhwave. Sarah kept losing her earplugs so added a loop to the back of her wetsuit so she could keep them together between surfs. Simple. Effective. Like the solution she found for wearing a hood without dreading up her long blonde hair.

“Just last week I cut a hole in my hood up here for my ponytail,” she explains showing me the prototype. “I was sick of taking my hood off to find my hair was a matted mess. I’ve tried plaits, ponytails, buns, everything – nothing works. It takes me two hours to brush it out. And so I put a hole in the top of my hood and I pull my ponytail out – it’s awesome.”

Sarah’s eyes light up as she offers an insight into the whirlwind of ideas streaming through her mind. I imagine Geoff and Paul, way back in 1987 when it all began, with a similar sparkle in their eyes, brimming with energy at where they might lead the brand next. It makes me proud to think we have a real New Zealand surfing brand with a compass bearing that places equal weight on sustainability and innovation.